Welding tables should be made of materials that lend you confidence, not compromise your precision. A great table isn’t just a surface; it’s the foundation of your workflow, the stage on which every joint and filament comes to life. The right material choice determines flatness, durability, heat handling, and the ease with which you clamp, mark, and assemble.

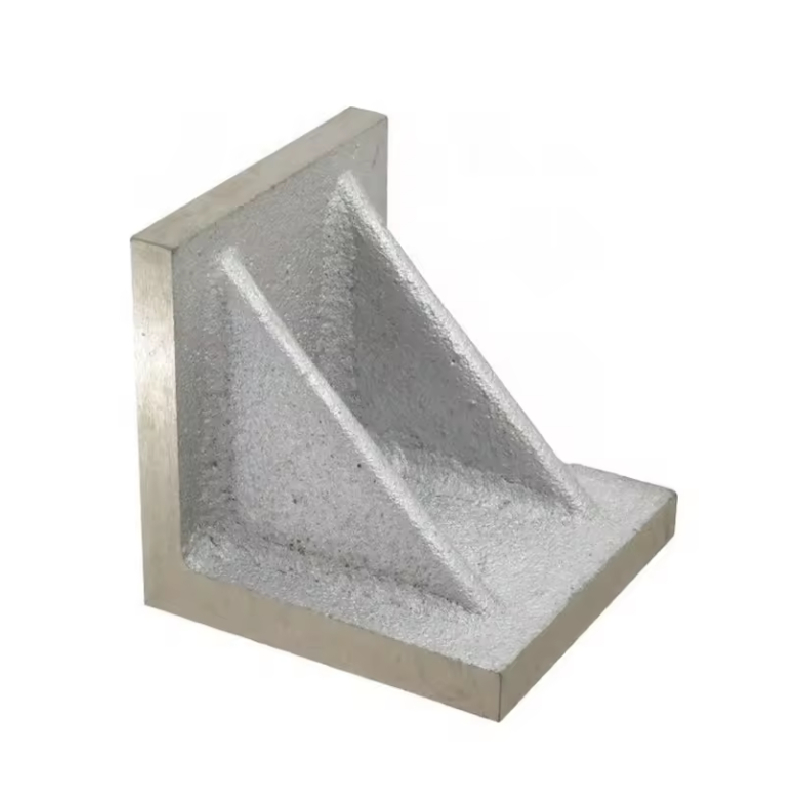

Two workhorse options dominate the serious shop: cast iron and steel. Cast iron tops excel in rigidity and long-term flatness. They absorb vibration, resist sagging, and maintain a uniform reference point after years of heavy use. Their density also helps distribute heat from welds, reducing local warping and improving repeatability. But cast iron is heavy and can rust if neglected, so it benefits from a protective coating and proper humidity control. A cast-iron table with a ground, machined surface and a grid of T-slots or dog holes is a lifetime companion for steel and aluminum work alike.

Solid steel tops offer robust performance with a different balance. They’re usually easier to maneuver, repair, and re-flat via professional resurfacing. Steel is forgiving to welders who move fast, and it resists impact better than cast iron in some configurations. However, without careful design—thick profiles, stiff frames, and appropriate clamping systems—steel can warp under repeated heat cycling. A steel-topped table is most effective when paired with a precise frame, reinforced edges, and a dependable finish that slows corrosion and spatter buildup.

For lighter-duty needs or non-heat intensive tasks, alternatives exist. Phenolic resin boards provide excellent insulative properties and a clean, non-marring surface for delicate assembly, but they are not designed to bear heavy weld heat or high-load clamping. Stainless steel tops offer superb corrosion resistance and cleanability, ideal for environments with moisture or chemicals, yet they can be more expensive and can show heat discoloration if not properly managed. Aluminum tops are tempting for their lightness but are typically less rigid and can deform under intense heat without careful engineering.

Beyond the material, the value of a welding table lies in its system: a guaranteed flat top, uniform thickness, a robust support frame, and a well-designed grid of T-slots or holes for clamps and fixtures. Whatever you choose, the best welding table should be made to endure, to stay flat, and to help you weld with focus and speed—so you can turn every project into a precise, repeatable performance. Invest in the material that best fits your work—and your workshop will thank you for years to come.

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.