Precision is a daily discipline in any workshop, and the thread gauge is your first line of defense against misfit parts. When people search for “thread gauge price,” they often expect a single number. But price is a signal, not a verdict. The real story sits in quality, versatility, and reliability that saves you time and prevents costly mistakes.

Prices for thread gauges vary widely, depending on material, range, and standard. Basic, entry‑level gauges—often plastic or simple steel rings—can start as low as a few dollars to around ten or twenty dollars. They’re useful for quick checks in low‑tolerance environments, but you trade durability and long‑term accuracy for the price. Mid‑range gauges, featuring stainless steel bodies, a broader thread range, and clear engravings, typically fall in the range of twenty to a hundred dollars. They deliver repeatable measurements with better resistance to wear, and many come in handy sets for multiple thread standards.

High‑end, professional thread gauges with calibration certificates and traceability can range from a hundred to several hundred dollars. These instruments are built for precision‑critical tasks: fine pitch threads, exotic materials, or aerospace and medical components. The extra cost buys you tighter tolerances, stabilized performance over time, and documented calibration that your quality system can rely on. In other words, the thread gauge price should reflect the value of consistent parts, reduced downtime, and fewer inspection errors.

Several factors drive price. Material and finish matter—hardened steel, corrosion‑resistant alloys, and laser‑engraved scales resist wear and misreadings. The measurement range and thread standards covered (UNC, UNF, metric M, and special pitches) influence complexity and cost. Calibration status, certification (ISO, NIST), and the availability of a calibration service or warranty can add value that saves money in the long run. A gauge that comes with a sturdy case, easy‑to‑read markings, and a formal certificate often ends up cheaper per correct measurement than a cheaper tool that needs replacement sooner.

How to choose without overpaying: define your thread standards, identify the required ranges, and consider the harmony between price and performance. Look for tools with clear optics, stable graduations, and a supplier who offers calibration or repair services. Read reviews about repeatability and durability. Invest in a gauge that matches your production tempo—faster work demands more reliable instruments.

Ultimately, the right thread gauge price is the one that aligns with your accuracy needs and your bottom line. Choose quality that pays for itself with every measurement.

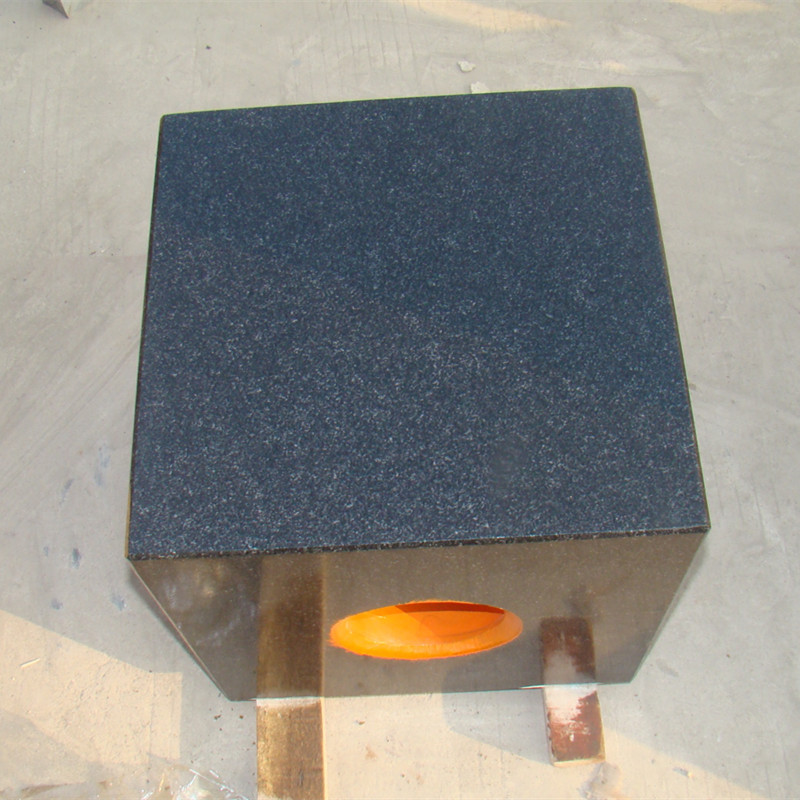

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.