Pump Check Valves: The Quiet Guardian of Your Pipeline

Every pumping system faces a single, stubborn threat: backflow. A pump check valve—the unglamorous, reliably silent guardian—keeps the liquid moving forward and never turning back. When placed in the right location, it pays for itself with reduced downtime, cleaner processes, and longer equipment life.

What is a pump check valve? It is a one-way valve that allows flow in the desired direction while automatically closing to prevent reverse flow. This simple mechanism shields pumps, meters, tanks, and sensors from back-siphonage and reverse pressure spikes. In other words, it protects your investment, your product, and your people from the chaos that backflow can unleash.

There are several styles to suit different needs. Swing check valves rely on a hinged element that swings closed when flow reverses. Tilting-disc valves use a disc that tilts to seal the seat. Ball check valves employ a sphere that seals against a seating surface, often with a spring assist for quick response. Each design has its strengths: swing valves excel in low-head systems; tilting-disc models offer quick response and compact sizing; ball checks provide reliable sealing in small-diameter pipes. Material choices—stainless steel for sanitary or corrosive services, bronze for water systems, engineered polymers for chemical plants—determine durability, temperature limits, and chemical compatibility.

Choosing the right check valve is not about size alone. It’s about knowing your process: inlet pressure, flow rate, temperature, viscosity, and the potential for solids or slurry. Key considerations include pressure drop (how much energy the pump must expend to push fluid through the valve), seat integrity, leak-tightness, and resistance to clogging. Reliability comes from quality materials, precise machining, and proper installation. Certifications and standards (such as ISO, API, or ASME) add confidence when selecting valves for critical applications like drinking water, food and beverage, or oil and gas.

The business case is compelling. A dependable check valve reduces shut-off events, protects seals and bearings, minimizes water hammer, and lowers maintenance costs. It also improves product quality by preventing contamination from reverse flow. In industries where uptime matters, even a small, well-chosen valve delivers a measurable return on investment.

Ready to upgrade? Start with clean specifications, choose a reputable product line, and consult with a valve specialist to match valve style, material, and rating to your system. A well-chosen pump check valve is more than a component—it’s peace of mind, ensuring every drop flows forward, always.

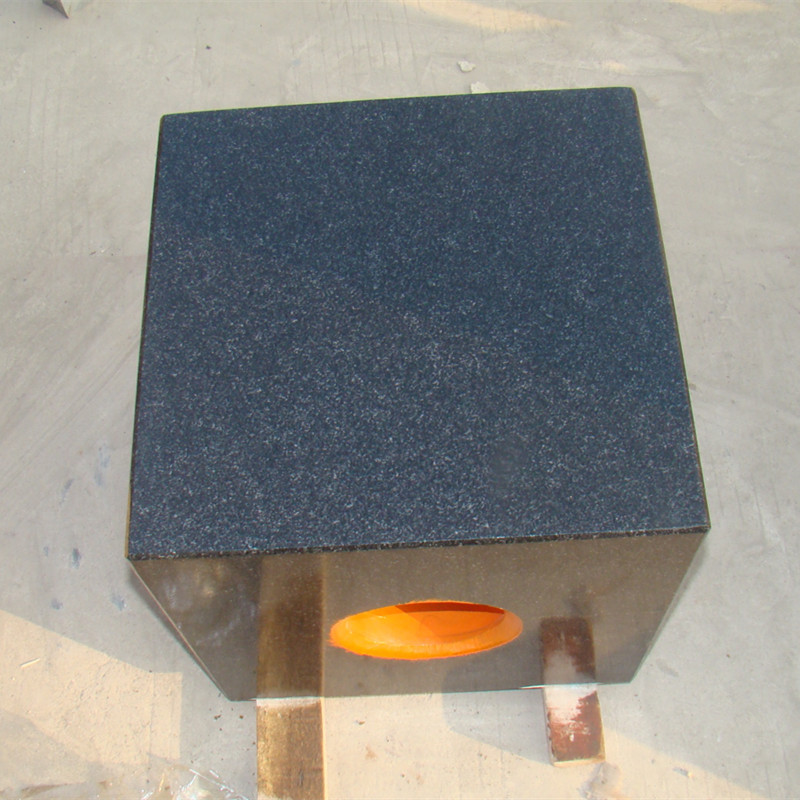

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.