The precision granite cube does not shout. It waits, unassuming, at the heart of precision laboratories, guiding every measurement with quiet authority. In a world where an inch can bend outcomes and a decimal point can determine a life-saving decision, the cube offers a stubborn, unwavering reference.

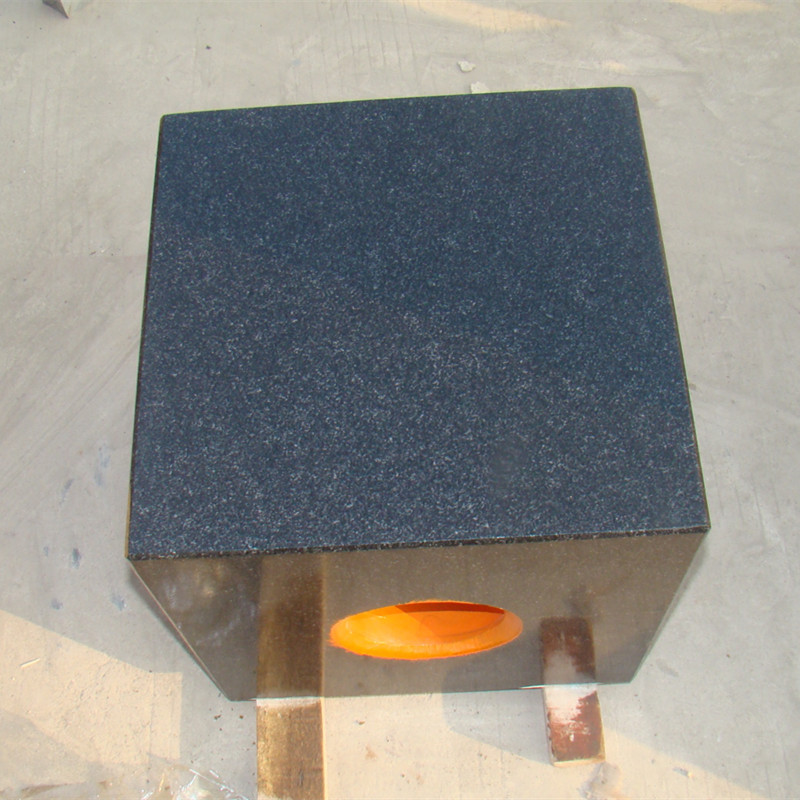

Granite may look ordinary, but its virtue lies in physics: extremely stable, with minimal thermal expansion, and an unyielding surface that resists scratching and wear. A precision granite cube is carved from high-grade stone, then milled, lapped, and polished to meet exacting tolerances. Each edge is square, each face flat, and each cube arrives with a certificate of accuracy, traceable to national standards. The workmanship is patient: the surface is finished to a texture that invites measurement while dismissing noise.

In practice, engineers place the cube on a calibration bench and use it as a reference plane for coordinate measuring machines, laser interferometers, and optical benches. Its flatness travels through the instrument, establishing a baseline that translates into trustworthy data across the entire workflow—from prototype development to quality assurance. Because granite’s thermal inertia slows the drift that bedevils other materials, a well-cut cube remains reliable from dawn to dusk in workshops that swing between rooms and climates. It is simultaneously a tool and a symbol: a reminder that accuracy is a habit, not a hope.

Our precision granite cubes are available in common sizes—50, 100, and 150 millimeters—each manufactured to a stated flatness and squareness; many shipments include surface finishes ranging from a matte, low-reflectance texture to a lightly polished face for easier optical contact. For clients who demand more, we offer bespoke tolerances, additional milling, and a certificate of traceability showing measurement results from calibrated instruments. Every cube is inspected in multiple orientations to confirm uniformity, then packaged to survive the rigors of routine lab life.

Some customers pair the cube with accessory stands, alignment plates, and anti-vibration bases. Our cubes are shipped in protective crates with desiccants and humidity control to preserve stability in transit and storage. For teams venturing into metrology for the first time, we provide training, calibration planning advice, and maintenance checklists to keep your reference true year after year.

If your measurement system depends on a calm, consistent reference, the precision granite cube is not merely a component—it’s a promise kept in stone. Discover how this unassuming cube can stabilize your process, sharpen your insights, and elevate every decision that hinges on numbers.

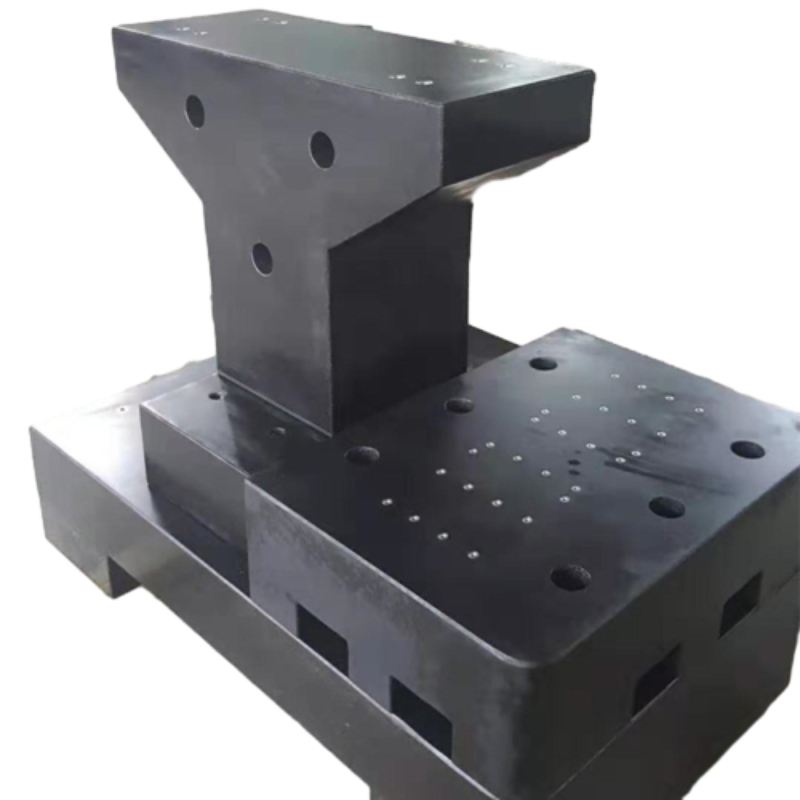

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.