Imagine a home or facility where every drop of water flows forward, never sneaking back to contaminate the source. That is the quiet power of installing a check valve. It acts like a one-way door for liquids, stopping backflow, protecting your drinking water, and stabilizing pressure in pumps, irrigation lines, and industrial systems. When chosen and placed correctly, a check valve pays for itself in peace of mind and fewer headaches.

Choosing the right valve is the first step. Check valves come in several styles—swing, ball, and lift—each suited to different fluids, pressures, and temperatures. Materials range from brass and stainless steel to PVC for milder environments. Size matters: a valve that’s too small creates resistance; one that’s too large wastes cost. Look for a design with a reliable seal, a durable seat, and a resistance to wear from your routine flow. In critical systems, consider a valve with a clear stem or indicator showing it is open and functioning.

Installation is where theory becomes protection. Before you begin, shut off the system, relieve pressure, and drain the line. If possible, isolate the valve with shut-off valves on both sides. Clean and inspect the pipe ends; remove burrs and old sealant. Install the valve in the direction of flow, following the arrow molded on the body. For threaded connections, apply appropriate sealant or tape; for flanged connections, use gaskets and proper bolts; for welded or soldered joints, ensure a clean, leak-tight bond. Keep the valve accessible for inspection and maintenance, and avoid placing it where it could be struck or buried in debris.

A simple checklist can keep your installation reliable:

- Verify flow direction and correct orientation for your header.

- Ensure clean, undamaged pipe ends and proper connections.

- Use the correct sealant, gaskets, or welds as required.

- Do not overtighten threaded joints; hand snug plus a light turn is often enough.

- After assembly, slowly re-pressurize and check for leaks around the body and joints.

Testing and maintenance complete the cycle. After the system is pressurized, observe for backflow or leaks and listen for unusual hammering. Periodically inspect the valve for corrosion, gunk build-up, or sluggish operation. If the valve fails to seal, or if you hear backflow, replace it promptly. A well-maintained check valve not only protects your water supply but extends the life of pumps and downstream equipment.

Invest in a quality check valve and a moment of proper installation today, and you’ll enjoy cleaner water, steadier flow, and greater confidence tomorrow. If you’re unsure about any step, consult a licensed professional to tailor the choice to your system’s needs.

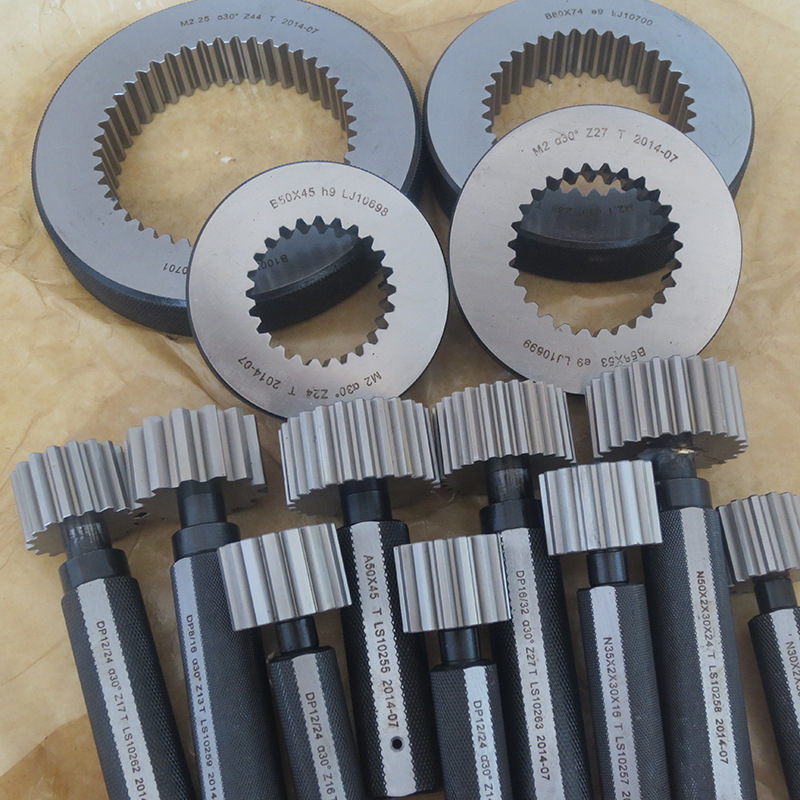

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.