Every piping system depends on one quiet guardian: a full flow check valve. It sits downstream of your pump or mixer, waiting for the moment when flow reverses, and then it seals with reliability. The result isn’t just protection; it’s peace of mind that your process remains steady, clean, and efficient.

A full-flow (or full-bore) check valve is designed so the bore stays unobstructed when the valve is open. That means near-zero resistance, minimal turbulence, and less energy lost to friction. When backflow threatens, the valve closes swiftly and seals tight, preventing contamination and protecting downstream equipment, downstream sensors, and your bottom line.

Why does this matter? Because backflow can trigger costly downtime, pump cavitation, and sudden pressure surges that ripple through your system. In contrast, a full-flow check valve delivers smooth, predictable operation. It’s robust against corrosion and wear, compatible with a wide range of media—from clean water to viscous slurries—and built for long service in demanding environments, whether it’s a refinery, a municipal water network, or an HVAC loop.

Applications span power plants, chemical processing, water distribution, wastewater treatment, and food and beverage lines. In every sector, a full-flow check valve protects pumps, preserves product integrity, and keeps your operations compliant with safety and quality standards.

Key features to look for include a true full-bore design, a reliable seating system, corrosion-resistant materials (stainless steel, bronze, or alloy bodies), and a seat that maintains a tight seal over thousands of cycles. Many models offer easy inspection and maintenance, compact dimensions for tight plant footprints, and flexible connection options—flanges, wafer, or butt welds—to match your piping.

Choosing the right valve isn’t just about size. It’s about lifecycle cost: lower energy consumption thanks to low head loss, fewer backflow events, reduced maintenance, and better protection for pumps and sensors. It’s also about service—manufacturer support, spare parts availability, and engineering guidance to ensure correct installation and sizing.

If you’re designing or upgrading a system, a full-flow check valve is a smart partner. Speak with a trusted supplier to tailor the valve to your media, pressure, and cycle requirements. With the right valve, your process runs cleaner, safer, and more efficiently—today and for years to come.

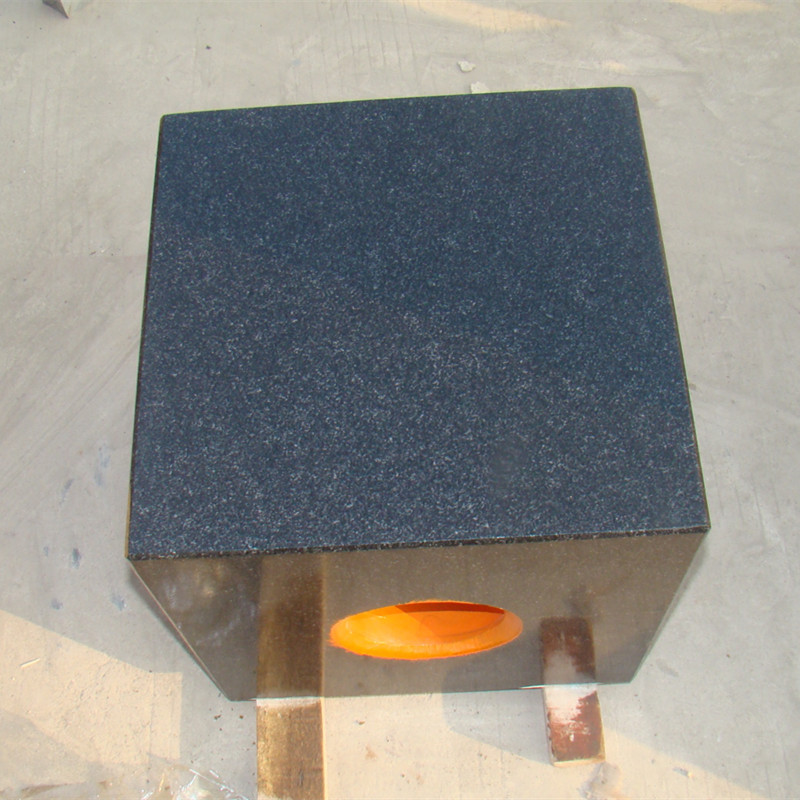

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.