Knife gate valve types: choosing the right guardian for slurry and strain

In industries where slurries, viscous liquids, and abrasive media rule the day, knife gate valves stand out as dedicated problem-solvers. Their blunt-edged “knife” slices through debris and seals against harsh media, delivering reliable isolation and clean shut-off where ordinary valves fail. But not all knife gate valves are built alike. The secret to long uptime lies in matching the valve type to the duty, the media, and the maintenance plan.

Common knife gate valve types at a glance

-

Soft-seated single-disc wafer valve: A lightweight, economical choice for moderate slurries and clean liquids. The elastomer seat (EPDM, NBR, or FKM) cushions closure for tight shut-off and simple maintenance. Best when the pipeline operates within the seat’s chemical range and pressure limits.

-

Hard-seated (metal or ceramic seat) knife gate valve: Designed for the most abrasive slurries, high temperatures, and aggressive chemicals. The metal or ceramic seat resists wear far longer than elastomer seats, though it may require higher actuation torque. Ideal for long service life in harsh environments.

-

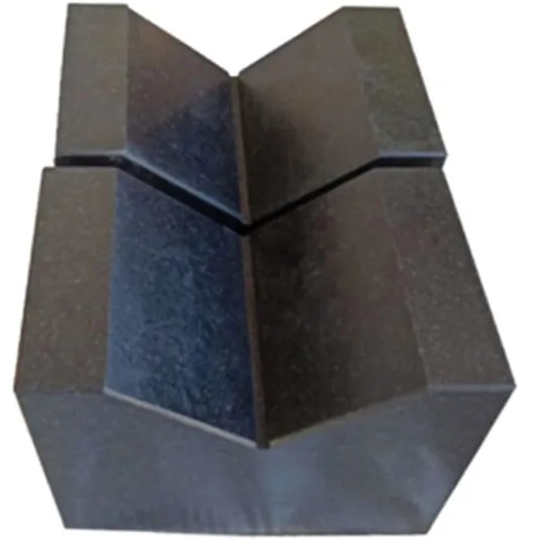

Double-disc knife gate valve: Two discs guard the seal area against heavy solids and extend seat life in challenging slurries. This design reduces wear on the seating surface and provides predictable shut-off under tough conditions.

-

Top-entry (maintenance-friendly) variants: A bonnet design that lifts away for easy access, reseating, and inspection without disconnecting the line. This is a practical choice for plants prioritizing downtime reduction and fast servicing.

-

Body styles: Wafer, Lug, and welded-end designs. Wafer valves are light and economical, suited to standard flanged connections. Lug designs allow isolation even in live systems, while weld-end versions provide maximum strength for high-pressure, high-temperature service.

-

Actuation options: Manual (handwheel or lever) for straightforward operation, and automated (pneumatic, electric, or hydraulic) for plants pursuing remote control, interlocking with safety systems, or high-frequency isolation cycles.

Key selection criteria for the right fit

-

Media and wear: If the media is highly abrasive or caking-prone, consider hard-seated or double-disc designs and reinforced end connections. For cleaner fluids, soft seats offer quieter operation and lower torque.

-

Pressure and temperature: Match end connection type and seat material to the service pressure/temperature class and corrosion potential.

-

Maintenance strategy: Top-entry designs or accessible seats reduce downtime; consider the availability of spare seals and simple reseating procedures.

-

Total cost of ownership: Initial cost vs. replacement intervals, downtime costs, and the value of automated actuation.

Choosing the right knife gate type is a strategic decision that blends engineering demand with operational realities. When you select wisely, you gain not only a valve that seals, but a partner in process reliability—protecting uptime, reducing risk, and supporting safe, efficient production.

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.