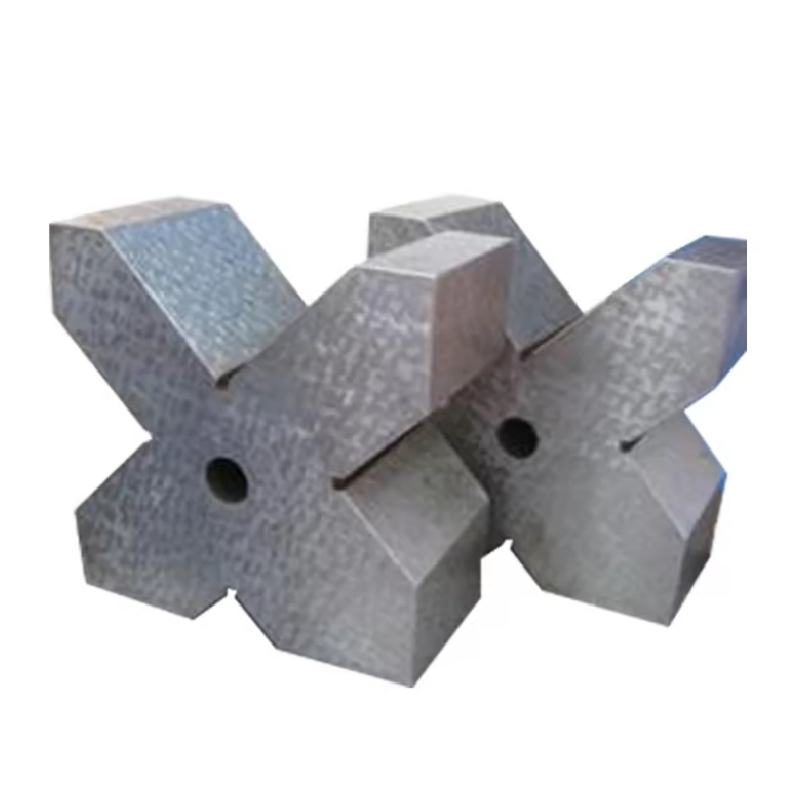

Behind every smooth-running plant is a guardian that works quietly to keep pumps, valves, and meters free from debris: the 4-flanged Y strainer. This heavy-duty filter combines a compact profile with four robust flange connections, offering secure integration into demanding pipelines and confident service in tough environments. The name “4-flanged” signals more than just size—it signals strength, alignment, and resilience.

In operation, the Y-shaped body houses a filtration element—a screen or perforated plate—that traps solids while letting the clean liquid pass onward. The two main flange ends bear the pressure of the line, while the additional flanges on the branch and the body distribute loads more evenly. The result is a compact unit that resists misalignment, reduces vibration, and minimizes leaks—critical advantages for high-flow, high-temperature systems.

Material options match the diversity of process industries. Stainless steel (304/316) provides excellent corrosion resistance for water, food, and chemical applications. Carbon steel or alloy grades extend service life in oil, gas, and high-temperature environments. Many 4-flanged Y strainers come with robust seals, optional coatings, and conform to industry standards such as ASME, API, and DIN, giving engineers confidence in long-term performance.

Maintenance is straightforward and cost-effective. The screen is replaceable, and many models feature a bolted or clamp-style cover for quick access. A drain or blow-down valve enables rapid removal of collected debris without dismantling the entire system. This design minimizes downtime and helps keep downstream equipment protected from wear and damage caused by contaminant ingress.

Choosing the right 4-flanged Y strainer depends on several factors: flow rate, pressure class, temperature, and the filtration requirement (mesh size or perforation). Screen materials—stainless steel meshes for precision filtration or wedgewire for durability—determine how fine the debris you trap will be. Consider also the pipe diameter and the available space for installation, as the four-flanged configuration can offer better alignment in tight or high-vibration environments.

Applications span diverse sectors: power generation, petrochemicals, water treatment, food and beverage, and HVAC systems all benefit from precise protection at the inlet of pumps and valves. By catching contaminants early, a 4-flanged Y strainer reduces downtime, extends equipment life, and sustains steady production with less maintenance.

In short, the 4-flanged Y strainer isn’t just a component—it’s a strategic safeguard. Choose quality, choose durability, and let this sturdy guardian keep your process clean, efficient, and reliable.

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.