Pin gauge sizes are the quiet heroes of precision engineering. In every workshop where tolerances matter, the right set of pin gauges can turn guesswork into certainty, and a single misfit into a costly delay. When a designer sketches a flawless part and a machinist doubts the hole, pin gauge sizes step in as the decisive link between intention and reality.

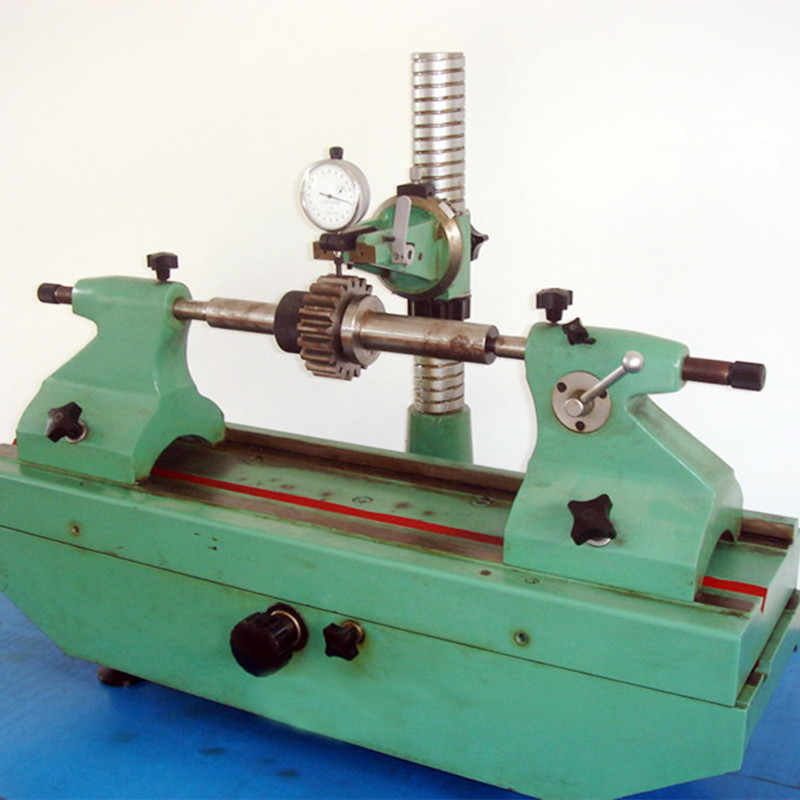

What exactly are pin gauges? They are a collection of hardened pins, each with a precisely defined diameter. To use them, you try pins in sequence against a bore, slot, or notch. The smallest pin that fits tells you the approximate size, while the next larger pin confirms the upper bound. This simple ritual translates into fast, repeatable measurements and helps ensure that every component will fit as designed.

Pin gauge sizes come in two common systems: inches and millimeters. Inch-based sets are typical in the United States and many industries, using decimal fractions that map neatly to hole tolerances. Metric sets prevail in Europe and Asia, offering millimeter diameters with decimal sub-divisions. The choice isn’t just about units; it’s about harmonizing with your primary drawings, tooling, and inspection habits. A well-rounded set covers the most frequently encountered ranges in your workflow, so you can gauge quickly without second-guessing.

Choosing the right pin gauge sizes means considering several factors. First, breadth: a broad range reduces the need for on-the-spot substitutions, saving time and avoiding misreads. Second, precision and tolerance: look for axes that are ground to tight, documented tolerances and, if possible, NIST or equivalent calibration traceability. Third, material and hardness: stainless or high-carbon steel pins with a Rockwell rating that resists wear will stay reliable through frequent use. Finally, packaging and labeling: a labeled case that clearly marks each size helps maintain order under pressure.

The benefits go beyond speed. Pin gauge sizes improve quality control by eliminating ambiguity, supporting uniform assembly, and catching mismatches before they ripple into defects. They suit everything from aerospace fasteners to tiny electronics housings, from automotive fixtures to custom jigs. And because they’re simple to clean, resistant to corrosion, and straightforward to store, they become a durable backbone of your inspection routine.

Treat pin gauge sizes as your daily assurance of fit. Invest in a trusted set, calibrate regularly, and keep them organized. When every pin aligns with a part, your production line hums, your artisans breathe easier, and your customers feel the difference in every precise, dependable product.

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.