Behind every perfectly finished part, there is a solid, silent platform. For precision machinists, a small granite surface plate is the unassuming hero that keeps everything honest. It sits on your workbench like a calm, neutral witness, ready to provide a flat, stable reference when speed meets scrutiny.

Granite is more than a pretty rock. Its natural composition delivers extraordinary surface stability and low thermal expansion, which means your measurements stay accurate as the room warmers or coolers nudge the temperature. The plate’s dense, vibration-damping properties swallow chatter from machines and tools, turning rough milling noise into a quiet routine of high-precision checking. On a small plate, you can still trust a full-size standard, because in metrology, certainty scales down as well as up.

Designed for the bench, a small granite surface plate fits where larger plates would crowd a corner or derail a workflow. Its flatness and parallelism are the marshals of consistent inspection: you can lay gauge blocks, set height references, and verify that a fixture is square without chasing stray errors. This makes it ideal for first-article inspections, setup checks, jig alignment, and routine calibration tasks. The compact footprint does not compromise capability; small plates are often enough to guide a clamps-and-fixture strategy that saves time on every project.

Durability is another quiet advantage. Granite resists corrosion, handles routine cleaning, and remains unfazed by the common workshop environment. With a good protective cover and proper support, a small surface plate can serve for decades, while maintaining its flatness with only periodic re-certification. And if you demand traceability, many suppliers offer ISO- or NIST-traceable certificates that stand up to audits and client requirements.

Caring for your plate is simple: keep the surface clean, stay away from harsh cleaners, and avoid impacts or dragging heavy parts across it. Use a soft, lint-free cloth and a mild solvent, replace worn leveling feet if needed, and cover when not in use. Your investment will translate into faster setups, fewer inspection errors, and a higher level of confidence in every measurement.

A small granite surface plate is not flashy. It’s reliable. It’s repeatable. It’s the quiet workhorse that makes precision feel effortless, turning everyday tasks into accurate, dependable results. If you build, assemble, or inspect with your hands, this compact ally deserves a place on your bench.

Whether you are a maker in a hobby shop, a contract manufacturer, or a research lab, a small granite surface plate scales with your ambitions. It harmonizes with other precision tools—calipers, micrometers, optical flats—turning disparate readings into a single trusted baseline. Invest in a plate today, and watch your setup times shrink, your rework vanish, and your measurements gain the confidence they deserve.

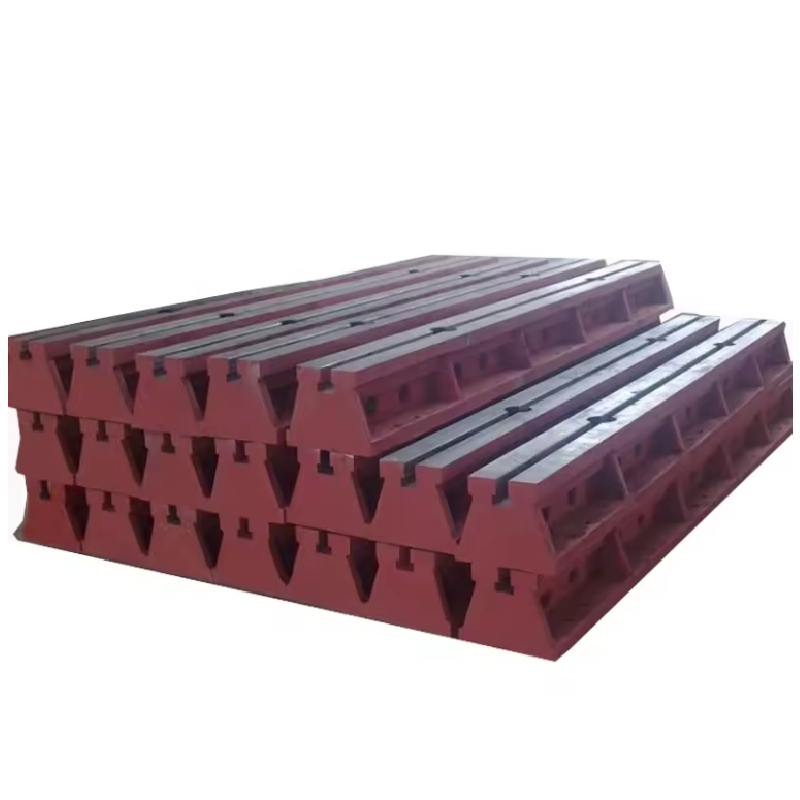

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.