Guide Rail Size: A Key Factor in Safety and Efficiency

When it comes to the design and functionality of rail systems, whether in transportation, industrial settings, or construction, guide rail size plays a critical role. While often overlooked, the correct sizing of guide rails ensures both safety and operational efficiency. Understanding this aspect is essential for those involved in planning or maintaining such systems.

Guide rails are designed to control and direct the movement of vehicles, machinery, or even pedestrians, preventing unintended deviations. The size of the guide rail directly impacts its ability to perform this function effectively. If the rail is too small, it may not provide the necessary containment or guidance; too large, and it could create unnecessary friction or occupy more space than required.

Factors Influencing Guide Rail Size

-

Load Capacity: The primary factor in determining guide rail size is the amount of weight or force the rail needs to support. Heavier vehicles or machinery require larger, more robust rails to ensure stability and safety during movement.

-

Speed and Impact Resistance: Guide rails must be sized to withstand high-speed impacts, especially in transportation systems. A larger, sturdier guide rail can absorb the force of a collision without compromising structural integrity.

-

Space Constraints: In many industrial or construction environments, space is limited. Here, selecting an appropriately sized guide rail is crucial for maintaining efficiency without overcrowding the area.

-

Material Considerations: The type of material used for the guide rail—whether steel, aluminum, or another alloy—also affects its required size. Stronger materials may allow for smaller rail dimensions while still providing the same level of performance.

Choosing the Right Guide Rail Size

When selecting the correct guide rail size, it’s vital to work with engineers or experts who can assess the specific needs of the system in question. Whether it’s ensuring a safe transport route for large trucks or optimizing the movement of industrial machinery, the guide rail must align with the system’s operational demands.

In conclusion, guide rail size isn’t just a technical specification; it’s a cornerstone of safety, performance, and durability in any system where movement control is critical. The right size will not only protect assets but also improve the overall efficiency of operations.

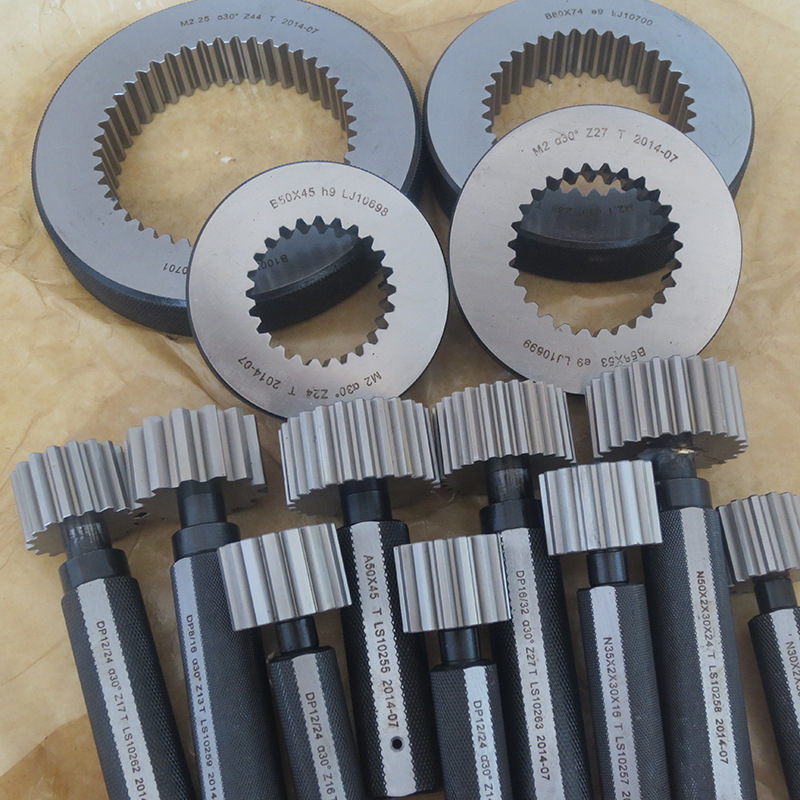

Golden AC generator | Filter DN50 | Metal Chain Link Fence | industrial metal supply With multiple core patented technologies and rigorous quality control systems (such as 9001 certification), we have established long-term partnerships with over 300 automotive manufacturers and component suppliers worldwide. Our products are exported to countries such as Europe, America, Southeast Asia, and Africa, with an annual production capacity exceeding 300000 units. We have won market trust with stable delivery and after-sales support.At the core of Storaen (Cangzhou) International Trading Co. portfolio lies its unparalleled expertise in cast iron welding platforms, measuring tools, plug gauges, ring gauges, and valves. These products, crafted with meticulous attention to detail and backed by stringent quality control measures, embody the hallmark of reliability and durability, catering to the diverse needs of industries worldwide.